Stating The Problem

Despite The rising tide of counterfeit drugs and the multitude of strategies employed to eradicate them, fraudulent practices with respect to SF medical products remain common.

Two key factors account for the influx of SF medical products:

1- Sheer Complexity of pharmaceutical supply chains and the great number of intermediaries involved gives rise to virtually inevitable security lapses along the supply chain which in turn provides the opportunity for counterfeits to slip through and permeate the supply chains.

2- The situation is further aggravated by the highly lucrative nature of fraudulent drug business. It is estimated that investing in fake drugs business yields profit margins often as high as 3000% which is 10 times the profit rate of trafficking heroin.

Despite the existence of global recognition of this problem, anti-counterfeit measures employed to date have proven to be either ineffective or at best impractical in the war against SSFFC medical products. Said techniques hereinafter referred to as “material based technologies” span a wide range of products like watermarks, holograms, color shifting inks, micro prints, to name but a few. Latest generation of material technologies involves adding chemical/biological taggants which can be later identified using highly sophisticated reagent systems. Though this technologies have been around for quite a long time, utilizing them has not resulted in any meaningful improvements with regards to curtailing the supply of fake medicine. The reason for this failure is that said measures are either inherently insecure or incommensurate with the specific needs of the pharma supply chain.

Solution Criteria

A fit-for-purpose solutions should :

- Be appropriately designed to address the specific issues faced by the pharmaceutical industry. Large majority of the aforementioned anti-counterfeiting measures were designed as general purpose tools and were never meant to address the problems specific to the pharmaceutical industry. This could prove problematic for a number of reasons; One particularly important reason being that the security value of the above mentioned techniques especially those implemented in a covert setting is strictly tied to the confidentiality of the formula as well as the authentication procedure.in the Pharma supply chains however, any anti-counterfeiting measures deployed preferably should and eventually will be publicized given the vastness of life sciences supply chains.

- Be preferably versatile and efficient enough to serve as standalone solution and pave the way for a unified global practice. This is important because the wide variety of technologies Adopted by manufacturers leads to further confusion among end users and serves the interests of counterfeiters.

- Remain valid for a reasonably long time. Moreover, must not be systematically reproducible should a case of compromise happen. Regardless of the technology type, incorporation of newly adopted measures into current procedures and educating the public accordingly would require major investments by companies and regulatory authorities in terms of time and money. However, we know from experience that proprietary formulas themselves fall prey to counterfeit within two or three years after emerging on the markets and therefore become obsolete. This implies a huge waste on investments made as companies are continuously forced to shell out for expensive upgrades.

- Preferably be cheap enough and free from proprietary constraints so that it could be implemented globally. Opting for material technologies however, usually implies a higher cost both in terms of licensing fees or royalties and expensive equipment such as handheld devices required for authentication.

- Preferably serve as a strong multifaceted deterrent to perpetrators of drug falsification/diversion. Material technologies fail to meet this criteria because in their case the only deterrent to criminals would be the cost associated with replicating/imitating the security element. However, once that is accomplished and the consignment of fake medicine finds its way through the convoluted maze of pharma supply chains, there are virtually no trails left behind and fraudsters can escape with little or no chance of detection at all.

Mass Serialization

Reshaping the approach

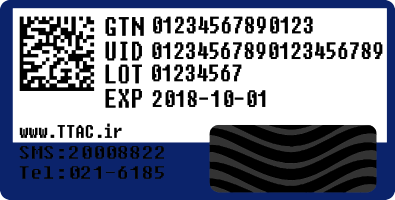

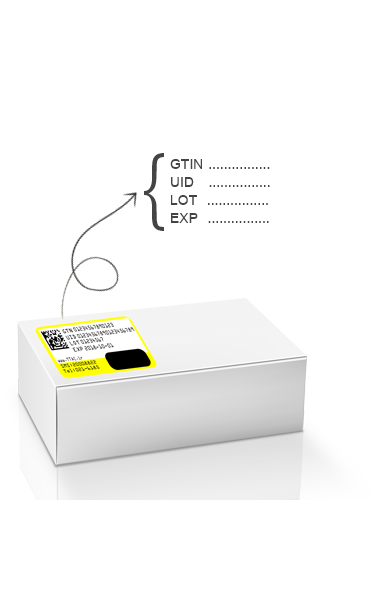

Mass serialization is a systemic approach for detection of counterfeiting, drug diversions and mishandling .for that purpose it requires unique alpha or numeric identifiers to be adhered to individual units-of-sale, tertiary packaging or pallets (depending on regulatory requirements) and thereby, provides the means to identify said units at each juncture throughout the supply chain.

Affixed serial numbers which may be in human readable form or scannable barcodes can be checked against a database to verify if the product is authentic. The database could be administrated by the manufacturing company, or relevant Government authorities. Authentication is usually accomplished by utilizing a dedicated mobile app or other suitable technologies such as SMS. Product authentication may be carried out by the end-user as well as otherwise pertinent supply chain participants such as a pharmacy during the initial stock check-in process and the response returned by the server might vary depending on the credentials of the user viewing it. A holistic serialization solution not only enables authentication at the point of dispensing, but also creates a data thread so that products could be traced backwards along their distribution channels.

Serialization based track and trace systems offer numerous advantages over previously employed measures as follows : A serialization approach can never be outdated and has theoretically infinite lifespan; it doesn’t rely on any proprietary formulas or equipment; could also serve as a valuable investigation tool and help detect how and from where a product entered the supply chain; tough a bit costly at the initial phase, is not subject to any royalties nor could it be systematically reproduced and therefore presents a viable investment; and finally aside from addressing the previously unresolved issues, could also serve as the foundation for future applications of importance to the health care industry.